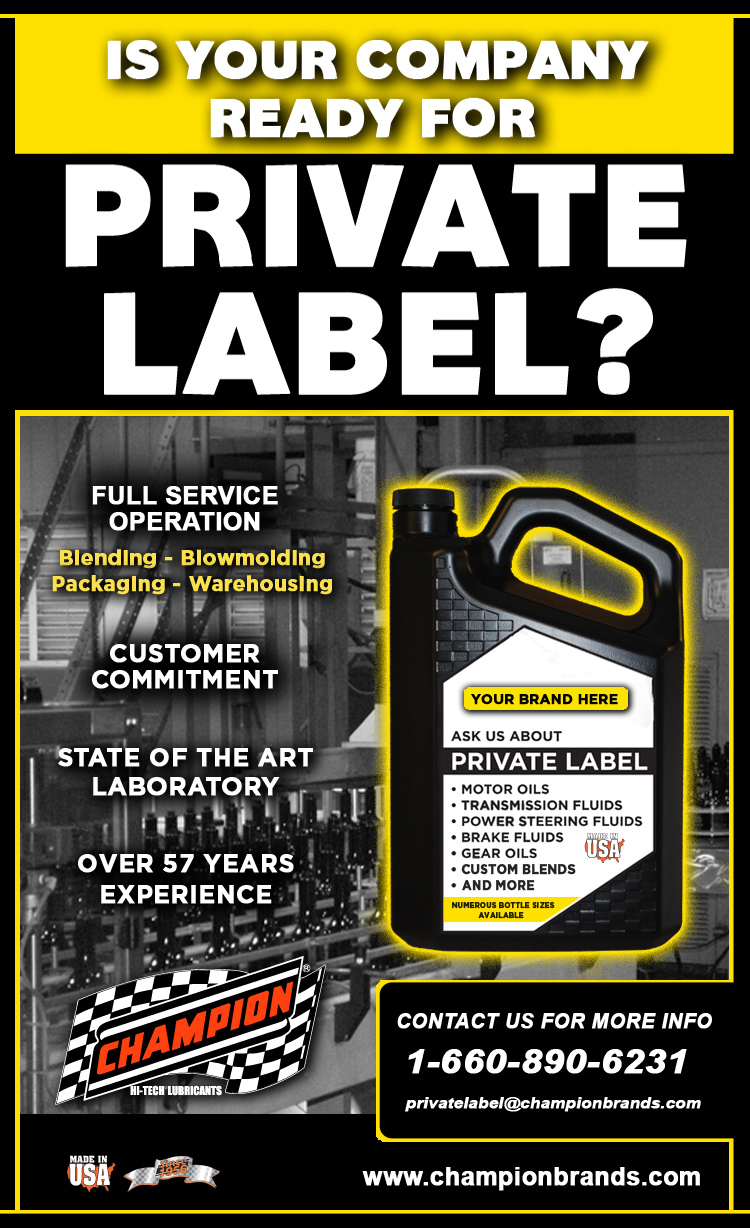

Manufacturing & Private Label

For over 50 years, Champion Brands has blended and packaged motor oils, gear lubes, and automotive chemicals for a number of Fortune 500 companies. Our packaging capabilities range from 2 oz. containers to rail car quantities from 10 filling lines. You can count on Champion Brands' total commitment to quality in every aspect of the blending, packaging and distribution of the products we produce.

Our Facility

Located in Clinton, Missouri, just 75 miles southeast of Kansas City, Champion’s 450,000 square foot plant accommodates more than 1.4 million gallons of bulk storage with convenient rail siding. The plant has 10 filling lines and an in-house blow molding assembly to produce HDPE and PVC bottles. The facility also contains state of the art volumetric and net-weight filling capabilities. Located in Clinton, Missouri, just 75 miles southeast of Kansas City, Champion’s 450,000 square foot plant accommodates more than 1.4 million gallons of bulk storage with convenient rail siding. The plant has 10 filling lines and an in-house blow molding assembly to produce HDPE and PVC bottles. The facility also contains state of the art volumetric and net-weight filling capabilities.

|

|

|

The net weight filling line is capable of filling 350 – 12 ounce containers per minute to exact weight specifications. Cans are de-palletized, labeled, filled, sealed, caped, coded, packed and palletized with only 3 operators needed. This line is capable of running metal or HDPE containers; in sizes ranging from 8 to 32 ounces. The net weight filling line is capable of filling 350 – 12 ounce containers per minute to exact weight specifications. Cans are de-palletized, labeled, filled, sealed, caped, coded, packed and palletized with only 3 operators needed. This line is capable of running metal or HDPE containers; in sizes ranging from 8 to 32 ounces.

The speed and versatility of this line makes it a high volume, cost effective solution for the many Fortune 500 companies that package product with Champion Brands.

Storage Capabilities |

Twenty-six blending tanks, ranging from 5,000 to 20,000 gallons, feed the elaborate pigging system designed to prevent cross product contamination. Rail siding and tanker truck offload locations provide the versatility to receive bulk fluids in sizes ranging from 5 gallons to 20,000 gallons. Twenty-six blending tanks, ranging from 5,000 to 20,000 gallons, feed the elaborate pigging system designed to prevent cross product contamination. Rail siding and tanker truck offload locations provide the versatility to receive bulk fluids in sizes ranging from 5 gallons to 20,000 gallons.

|

|

|

Packaging & Production |

|

Champion Brands’ blow molding operation has the capabilities to produce HDPE and PVC bottles in sizes ranging from 4 oz. to 2.5 gallons in a wide range of colors. Champion’s bottle production utilizes 10% regrind material, essentially reusing and recycling otherwise unusable plastic. Champion Brands’ blow molding operation has the capabilities to produce HDPE and PVC bottles in sizes ranging from 4 oz. to 2.5 gallons in a wide range of colors. Champion’s bottle production utilizes 10% regrind material, essentially reusing and recycling otherwise unusable plastic.

|

Seven lubricant filling lines package engine oils, hydraulic fluids, specialty oils, fuel additives, and automotive fluids (power steering fluid, brake fluid, tire sealant). Each line has specific types of products that it can package.

|

Bottles are labeled, capped, heat sealed (if needed), coded, placed into cartons, and loaded onto pallets.

|

Quality Assurance & Testing

Champion Brands has a state of the art lab. While the lab’s primary function is to test the performance of products before they are packaged, the lab also has the tools to perform elemental analysis of fluids to blueprint the Champion Brands has a state of the art lab. While the lab’s primary function is to test the performance of products before they are packaged, the lab also has the tools to perform elemental analysis of fluids to blueprint the

various components of different fluids or test used fluid.

|

Logistics and Freight |

Champion Brands’ warehouse and transportation department is nearly large enough to be its own distribution center. Champion trucks service most of the Mid-West on a rotating schedule.

|

|

|